Realizza, Impara, Cresci

La tua esperienza 3D comincia qui.

Rivenditori Certificati:

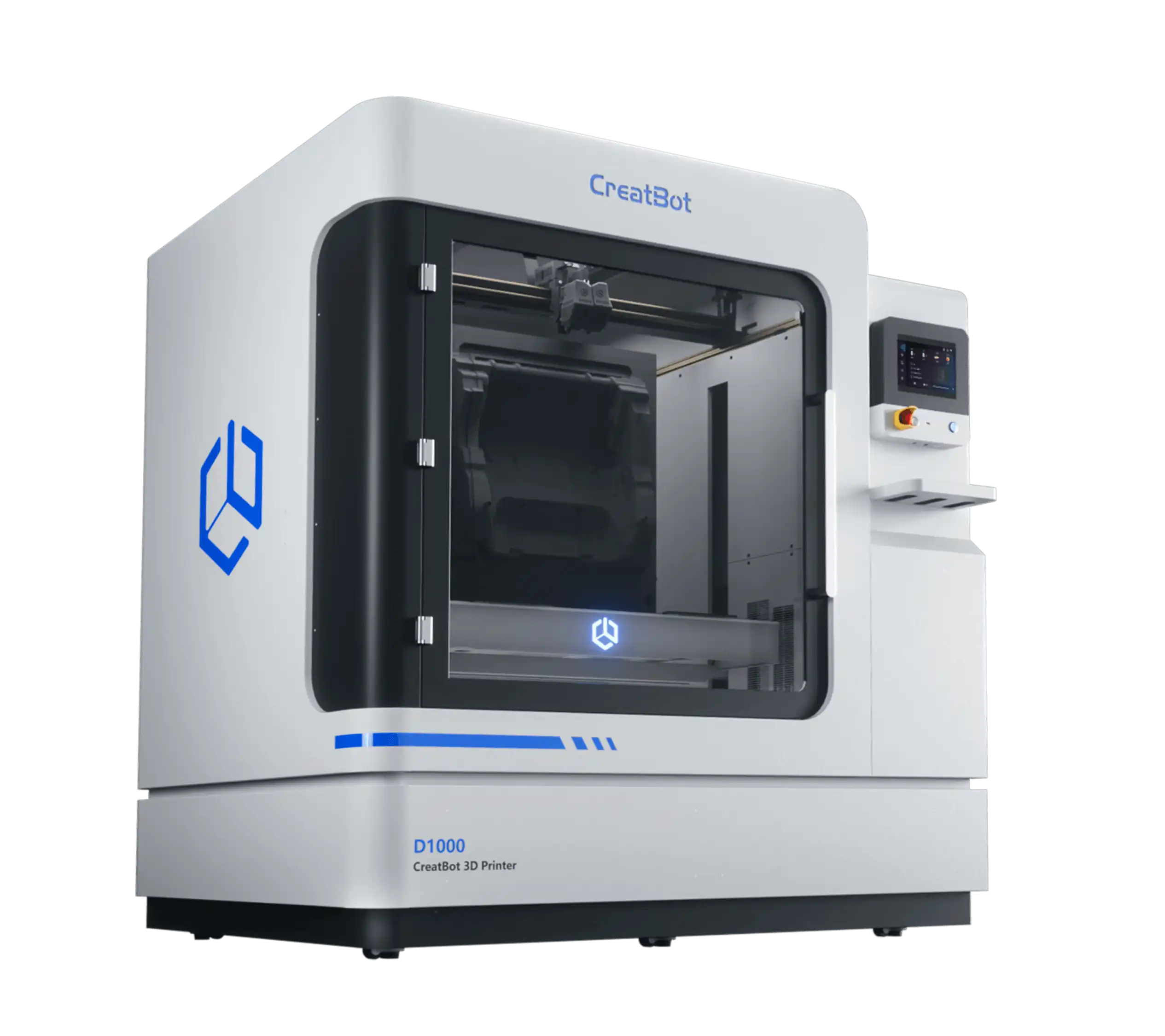

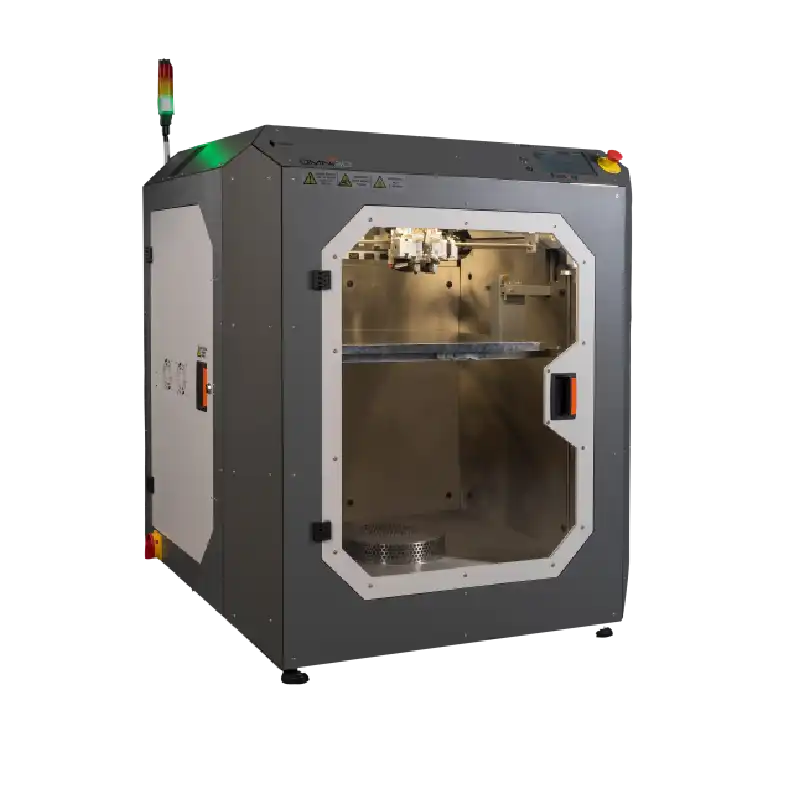

Stampanti 3D Professionali

Accedi all’avanguardia della manifattura digitale e delle fabbriche intelligenti con le nostre stampanti 3D di livello professionale. Converti i tuoi modelli 3D in manufatti tangibili con rapidità, riducendo significativamente i costi.

Scanner 3D Professionali

Leggi I nostri Ultimi articoli sul mondo delle stampanti 3D

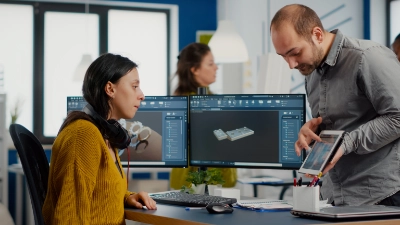

Assistenza Dedicata e Formazione Professionale

l nostro impegno nella formazione professionale e nell’assistenza dedicata rappresenta un pilastro fondamentale del nostro servizio, offrendo un vantaggio distintivo nel settore delle stampanti 3D. Attraverso un approccio personalizzato, forniamo sessioni di formazione approfondite, progettate per equipaggiare i nostri clienti con le competenze tecniche necessarie per massimizzare l’utilizzo delle loro stampanti 3D. Inoltre, il nostro team di assistenza dedicata è sempre disponibile per garantire che ogni problematica venga risolta con rapidità e efficienza, assicurando così una minima interruzione delle attività dei nostri clienti. Questo impegno nell’educazione e nel supporto non solo migliora l’esperienza del cliente, ma stabilisce anche una fiducia duratura e una relazione di valore con ciascuno di loro.

Spedizione internazionale in tutta Europa

Alcuni Nostri Clienti: